Advantage Of Our Flat screen printing machines:

Flat screen printing is first according to the color of the pattern, color production of a number of screen, with the frame fixed, screen on the part of the non-printing pattern mesh is cut off. After stretching and plate-making screen called color frame. During printing, paste the fabric on the long and flat surface, place the color frame on the fabric, add the color paste in the color frame, and use the scraper to scrape and press the color paste on the column of the color frame, so that the color paste can be printed on the fabric through the mesh hole of the screen printing pattern.

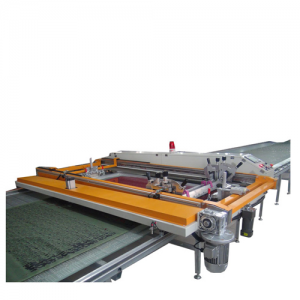

According to different processing method and the I art, flat screen printing machine can be divided into network dynamic flat screen printing machine (commonly known as bed plate printing machine) and moving two types of flat screen printing machine, flat screen printing machine and the network are divided into manual bed plate printing machine and semi-automatic bed plate printing machine, flat screen printing machine and cloth are divided into gap in and out of the cloth type and continuous in and out of the cloth type two kinds.

Specifications

A book with the first in the conduction band milky white sticky stick a blank white towel, then start the inverter drive cage three-phase ac asynchronous motor, the motor after the worm gear reducer reducer drive conduction band, when the guide bring a towel on the flat screen printing position is stationary, flat net box down with towel, fine circle magnetic steel bar net box placed at the bottom of the conveyor belt of reciprocating rolling, driven by magnetic field controller will be placed flat screen paint through the hollow out the patterns of the dyeing and printing to the towel. The pattern of the first color is printed, the mesh frame is lifted, the guide belt will send the towel to the next mesh frame position, stop and start the printing and dyeing of the second color pattern…… , until a number of colors (generally 8~10 colors) in turn, a color towel is completed, and the second towel followed by the first towel color printing…… Go round and round. After finishing the printing and dyeing of each towel, it will be sent to the tunnel type steam oven to dry, then wring, finishing, quality inspection and packaging until it is put in storage and delivered from factory.

Features

Flat screen printing machine printing flower back length range, wide range of screen surface, color, not easy to transfer color, can print contour clear and delicate pattern, plate making fast and easy, printing fabric bear the tension. Suitable for variety, small batch of light, high – grade fabric printing.