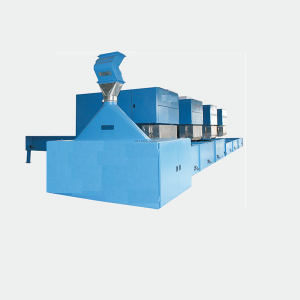

Textile Non- Woven Machines-Opener:

The process of untangling and removing impurities from tightly packed, entangled fibers. All kinds of fiber materials used in spinning, such as raw cotton, wool, chemical staple fiber, cotton, linen, polyester, rags, etc., are mostly transported to the textile mill in the form of pressed bales. The packing density of raw materials is generally 200~650 kg/m 3, while the packing density of raw cotton in China is about 330~400 kg/m 3. In order to spin fine yarn, first of all, the raw materials need to be loosened, remove all kinds of impurities, evenly mixed. The opening quality of fiber raw materials has an important influence on the quality of semi-finished products and yarn as well as the saving of materials.

Specifications

- WORKING WIDTH: 1300mm

- DIAMETER OF OPENING ROLLER: Φ450mm

- CAPACITY: 50~200KG/H

- CONVEYER BELT: WOODEN APRON

- POWER: 6.95KW

- DIMENSION: 3700(L)X1900(W)X950(H) mm

- THE MACHINE FRAME IS MADE OF 10mm THICK HIGH-QUALITY STEEL BY WELDING

- AND ANNEALED UNDER HIGH TEMPERATURE TO ELIMINATE INTERNAL STRESS.

- 1.8 FEEDING ROLLER: TWO PAIRS, DIAMETER OF ROLLER IS Φ70mm, PRESS BY SPRING.

- FAN: NO.5, DRIVEN BY 4.0KW MOTOR.

- THE SCRAP IRON SNATCHED BY MAGNET IN THE BOXROOM.

Features

It is mainly used to release fibers, cotton, textiles and other materials, which can make large pieces of tangled fibers loose into small pieces or bundles by tearing. At the same time, it is accompanied by mixing and removing impurities in the process of release. The loosing machine is generally composed of a pair of feeding rollers or feeding rollers and a loosing tin forest, loosing tin forest is equipped with corner nail or comb needle or needle cloth or porcupine beater, for loosing more thoroughly, some also in the tin forest is equipped with work roll and stripping roll. Different structure makes its opening effect, mixing effect, removing effect has the obvious difference, therefore should use the different form on the different request production line opening machine.