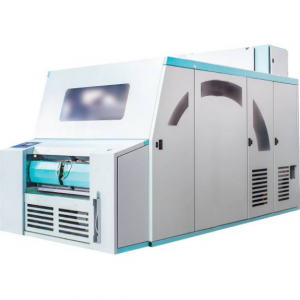

High Speed Circular Knitting Machines:

For yarn knitting machine is made up of frame, organization, transmission mechanism, lubrication dust clean mechanism, electrical control, force mechanism and other auxiliary equipment. In the transmission mechanism, the yarn be transmitted by send yarn to weave area, guide the yarn feeding beard needle hook weaving, knitting needle movement along a triangular course, complete silence and ring, kinking, lap, lap, which is held the ring back from time to tome in the needle old coil, prevent its buoyancy, pull mechanism will form the fabric of continuously pull evenly and fabric package into a certain form, to set off, revolutions, the machine will automatically stop, to complete a cloth production. In this process, there are dust removal mechanism, automatic oil injection system, automatic stop device and so on at the same time, to ensure the normal operation of the machine and the quality of the cloth.

Specifications

Knitting production can be woven into a variety of gray cloth, after cutting, sewing and into a variety of knitwear, but also can be directly woven products, to make full or part of the forming products. Forming process can save raw materials, simplify or eliminate cutting and sewing process, and improve the performance of products. Knitting production has developed rapidly because of its short technological process, strong adaptability of raw materials, fast variety change, wide range of product use, low noise and low energy consumption.

Features

Circular knitting machine, technically known as circular knitting machine (or circular knitting machine). Due to the knitting circular machine of the loop system (enterprises called into the yarn or loop road, referred to as the road), high speed, high output, flower shape change quickly, good fabric quality, little process, product adaptability