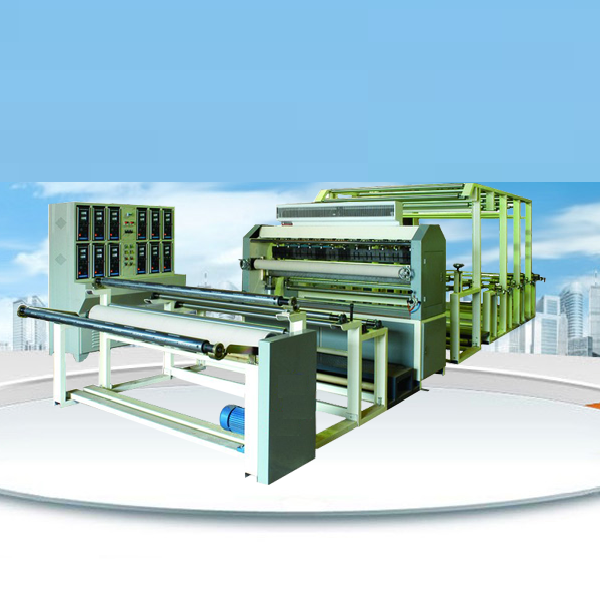

Advantage Of Our Ultrasonic Sewing Machine:

The grey cloth is first dipped and rolled with raising agent, then dried and stretched, and then finished by grinding on a special grinding machine. The roller coated with sand is used for friction on the cloth surface, so as to grind out a layer of nap.

Specifications

- Frequency: 15 KHZ,

- Output power :12KW

- Motor power: 3.7kw

- Efficiency: 8 to 20 m/MIN

- Effective size: 1800mm

- Roller diameter: 136mm

- Working length: 1800mm

- Weight: 45000 kg

Features

- Mainly used for knitting fabrics, suede fabrics and other components of the surface grinding wool

- According to the requirements of cloth wool grinding frequency conversion speed adjustment, touch screen control easy operation

- The rubbing rod can move horizontally to reach the evenness of rubbing and avoid the straight strip.

- The cloth joint self-inspection device can avoid the breakage of the cloth joint.

- The contact surface between cloth and grinding roller can be adjusted pneumatically according to the thickness of grinding wool, with precise and stable tension.

- Carbon fiber is suitable for imported fiber, and sandpaper roller can be replaced.